About Pp Flexo Printed Bag

Specification

| Minimum Order Quantity | 250 Kg |

| Base Material | PP (Polypropylene) |

| Application | Food Packaging |

| Pouch Size | 12" to 30" |

| Pouch Pattern | Printed |

| Pouch Lamination | Double Layer Lamination |

| Printing Technique | Flexographic |

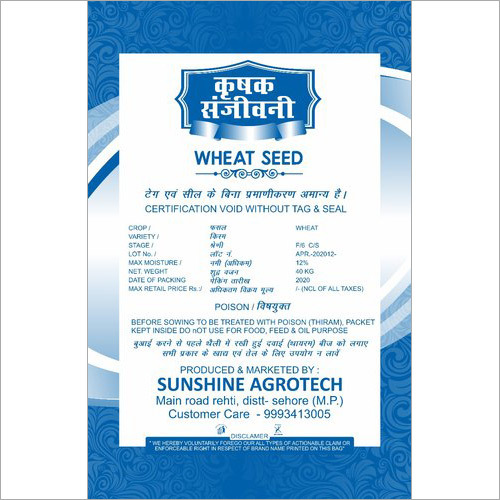

Advanced Printing for Premium BrandingLeveraging flexographic printing technology, PP Flexo Printed Bags showcase brand details and product information with clarity and color vibrancy. The printing process ensures durable and high-quality graphics that enhance product presentation, making them ideal for companies looking to reinforce brand identity in agricultural markets.

Durable Construction for Agricultural UseBuilt from woven polypropylene, these bags are engineered for robustness and reliability, providing superior protection against moisture, tearing, and punctures. The top heat-sealed closure strengthens the bags integrity, ensuring safe transport and storage of various agricultural products.

FAQs of Pp Flexo Printed Bag:

Q: How are PP Flexo Printed Bags manufactured?

A: These bags are made by weaving polypropylene fibers to create a strong, flexible fabric, which is then printed with branding and information using flexographic printing technology. The top of the bag is heat-sealed to provide secure closure and prevent leaks.

Q: What benefits do PP Flexo Printed Bags offer for agricultural use?

A: PP Flexo Printed Bags provide excellent durability, moisture resistance, and enhanced branding through printed designs, making them ideal for storing and transporting agricultural products while maintaining product integrity and visibility.

Q: When should you use PP Flexo Printed Bags?

A: They are best used when transporting or storing agricultural goods that require reliable protection and clear product identification. Their varied sizes and strong construction make them suitable for many types of agricultural applications.

Q: Where are PP Flexo Printed Bags commonly sourced in India?

A: These bags are widely available from importers, manufacturers, and suppliers across India, catering specifically to the agricultural industrys packaging and transport requirements.

Q: What is the process involved in flexographic printing on these bags?

A: Flexographic printing uses flexible plates to transfer ink onto the polypropylene surface, creating high-quality, vivid graphics that resist smudging and fading, even in demanding agricultural environments.

Q: How should PP Flexo Printed Bags be handled and sealed?

A: The bags are designed with a top heat seal, ensuring quick and secure closure. This method helps maintain the contents safety during handling, storage, and transportation.

Q: What makes these bags suitable for branding?

A: The surface of the bags is specifically prepared for printed graphics, allowing manufacturers to display logos, product details, and brand information prominently, enhancing market recognition and compliance with packaging regulations.